2018-10-11

News center

There is currently no information content displayed

الصفحة السابقة

1

الصفحة التالية

Contact us

Phone: 13960781998 (Miss Lin)

Email: gh912@esdtech.cn

Address: Building 1 # B, No.1 Chashan Road, Science and Technology Park, Mawei District, Fuzhou

Message

Copyright © Fuzhou Guanhong New Materials Technology Co.,Ltd All Rights Reserved

Powered by saa

| Material | Characteristic |

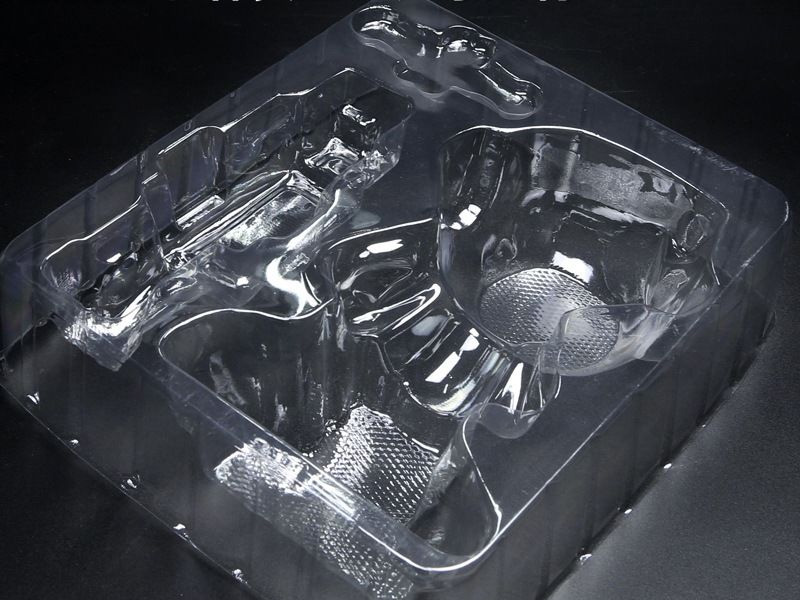

| PC | The material surface is good glossiness, good heat resistance, self extinguishing ability, excellent impact performance, small expansion coefficient, stable size, excellent electrical and chemical resistance, good fatigue strength, and complies with the EU ROHS directive and strict UL safety regulations. The UL94 fire rating reaches VTM-0, and there are various surface textures |

| PP | The material is semi transparent, particularly soft, with good toughness and high temperature resistance. It is the main material for food blister tray packaging and can be heated in a microwave oven |

| ABS | Good toughness, high strength, and corrosion resistance |

| PET | Hard texture, good toughness, high strength, bright fur surface, non ignitable, and can reach food grade. Transparent and multi-color sheet materials. Commonly used for blister packaging with high export requirements. Characteristics: PET cannot be hot pressed (high frequency fusion) |

| PS | Low density (light weight), very good plasticity, poor toughness, easy brittleness, and cannot be made into transparent materials. Therefore, it can only be made into base type blisters, as they are prone to cracking, so this type of blister is not suitable for recycling |

| PVC | Commonly used blister materials, with soft texture, strong toughness, and good plasticity, can be made into transparent and various colors, and are commonly used in various electronic, cosmetic, toy and gift blister products |